BLOG

MODULAR SUPPORT SYSTEMS REPLACE CLASSIC MANUFACTURING

The first thing that stands out in mechanical installations is how the installation components are supported. When we look at the productions made today, the practices brought by the habits in many productions stand out. Most of the time, wrong hanger products are used, and irregular trapeze installations can be encountered even in very large budget investments.

Modular support systems, which provide much more cost-effective solutions compared to the classical systems used in existing support applications, provide flexible installation opportunities in full compliance with the suspension requirements.

While modular support systems can respond to all support solutions required for electromechanical installations, they also allow production to be made within certain quality, load resistance and aesthetic standards.

Unlike the classical support approach, the channel selections made by considering the work loads of the installation elements to be supported, make the support design exactly suitable for the needs, and waste and excess material usage are prevented.

With the use of modular support system, the need for welding labor is eliminated, and a great saving in time and labor is provided in revision installations that may arise as a result of project changes that occur during production.

Modular suspension systems, which are new but are increasingly used in serious and well-designed projects, are currently widely used all over the world.

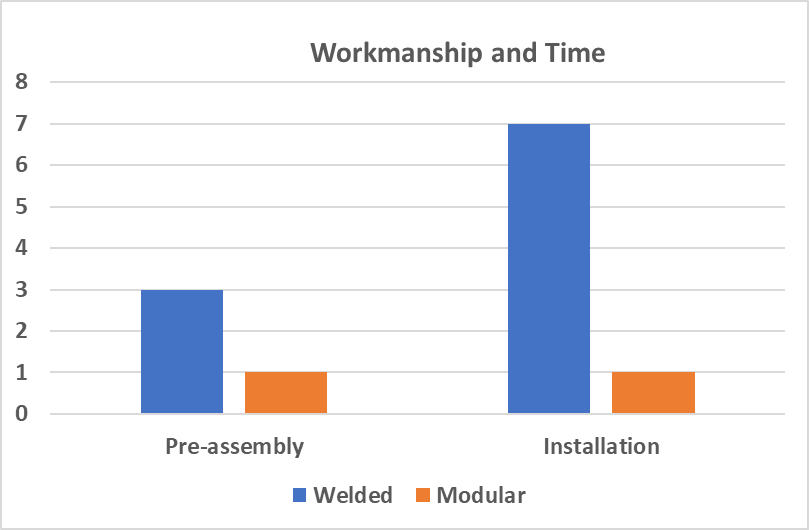

In the studies carried out, it has been revealed that during the manufacture of a simple pipe trapeze with modular suspension solutions, 3 times of labor and time savings are achieved in preparation for assembly and 7 times in the manufacture of the console.

Welded - Modular Comparison

It is very important to look for certain standards in the selection of profiles, which are critical components in the selection of modular support system products, to prevent quality problems that may be encountered during or after production. Although there is no regulation referring to the standard of such products, it will be sufficient to seek the conformity of EN 1993 – Eurocode 3, which is included in the European Norms. Eurocode 3 is a standard that specifies the standards that steel profiles used in buildings should have.

By choosing modular support systems, you can increase the production quality, profit from the assembly material and labor used, and save manufacturing time.

You can contact our company Darhan Yapı ve Industry about modular support systems, components, design and preparation of BOM lists for your projects.